Mycotoxin Risk Management Programme

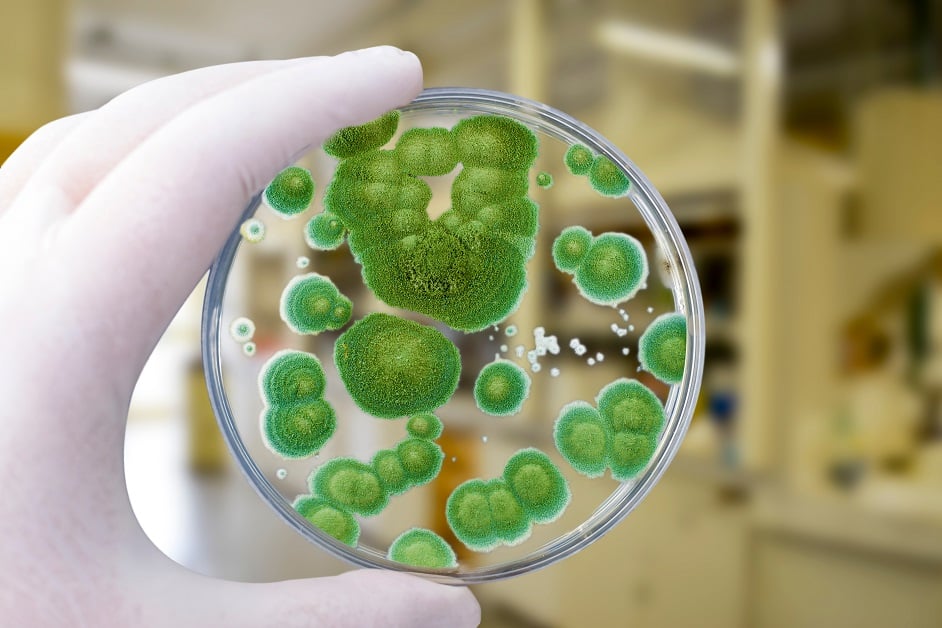

Mycotoxins produced by moulds are a growing problem in feed production. Selko’s integrated mycotoxin risk management programme enables feed producers to make data-based decisions and use mycotoxin control solutions more precisely to address this issue.

The key to mycotoxin control is risk management; taking an integrated approach, rather than isolated measures, leads to a better outcome. Our complete risk management programme enables you to make decisions based on knowledge and data, and to use Selko's TOXO products in the most effective way. It allows for active monitoring of risks, so you can be more confident about the quality of your products.

Global Mycotoxin Review 2023 - 2024

In this webinar recording, we explore insights from over 65,000 mycotoxin analyses conducted in 2023, offering invaluable strategies for effective risk management in 2024. Dr. Swamy Haladi, Selko’s Global Technical Commercial Manager, provides global-level guidance on navigating this extensive dataset. Joining him is Mr. Avinash Bhat, Technical Specialist at Masterlab, offering innovative perspectives on interpreting and forecasting the data. Gain expert insights to optimise mycotoxin risk management for your operations.

How do we do it?

Identifying the risks

To help identify the risk of mycotoxins in feed on the farm, we offer Mycomaster, a lateral-flow smart device that provides a reliable quantitative reading of the contamination levels in feed materials and compound feed. It enables rapid on-site, cost-effective and user-friendly analysis of six different mycotoxins: Zearalenone, Deoxynivalenol, Aflatoxins, Fumonisins, Ochratoxin and T2-HT2.

This easy-to-use tool gives results within 15-30 minutes, which means that feed producers can analyse mycotoxins themselves. It can also be connected to Trouw Nutrition's global data exchange system, allowing the review of data collected from all over the globe. Read more about this NutriOpt service, called Mycotoxin Adviser.

Ensuring proper quality control

Since mycotoxins are produced by moulds, it is important that raw materials and feed are stored properly at feed mill or farm level. Quality control is key: new materials should be tested upon arrival, so you can detect contamination levels and even reject raw materials if mycotoxin levels exceed guidance values.

Proper hygiene measures on the farm are also crucial to prevent mould and mycotoxin development at a later stage. For example, regular cleaning of feed troughs will prevent residue feed from getting mouldy. Pay special attention to silage, which can be prone to mould growth due to the favourable conditions during storage. Finally, animal performance should be monitored closely, to detect any symptoms of increased mycotoxin levels.

Applying powerful solutions

Once raw material or feed quality have been assessed and the mycotoxin levels identified, you may need to take action to prevent mycotoxins from affecting animal health and performance.

Studies around the world have shown Selko's TOXO products to be effective in mitigating mycotoxin contamination. Products from this portfolio can be applied if mycotoxin contamination occurs in raw materials or complete feed or incorporated into the feeding programme through premixes or feed.

Selko's TOXO products provide a complete solution for a broad spectrum of mycotoxins, through the combination of its three main modes of action, designed to support animal health and performance during mycotoxin exposure.

"Constant exposure to mycotoxins may lead to chronic toxicity and economic losses. A comprehensive mycotoxin risk management programme should be in place to prevent and reduce such economic losses."

Frequently asked questions

What is the role of a mycotoxin adsorbent?

Adsorbents, or binders can be very effective for certain mycotoxins, but not all. The physiological complexity in the gut may compromise binding efficacy and, therefore, it is not wise to rely on a toxin binder alone.

Can I rely solely on mycotoxin binders?

We recommend that you combine binders with other functional ingredients that can mitigate the toxicity of mycotoxins. An integrated binding and remediation strategy can help minimize the negative impact of mycotoxins on animal health and performance. TOXO-XL contains ingredients that support this combined strategy.

I use mould inhibitors to prevent mycotoxins – is that enough?

Mould control is important, but not alone sufficient to prevent mycotoxin occurrence. Since mycotoxins are metabolites of moulds, they can be produced even while crops are growing in the field. Once present, most mycotoxins cannot be removed through acidification or heating and other strategies are needed to prevent them from impacting animal performance. So, even when moulds are removed at any step of the feed production chain, mycotoxins that were already present will continue to pose a risk.

Is there a cumulative effect when low levels of mycotoxins are consumed over a longer period of time?

Absolutely, yes. Chronic exposure to multiple mycotoxins, though each may be at a low-risk level individually, can drive down animal health and performance.

MycoBite video series

MycoBites is a series with comprehencive and practical explanations about various topics in Mycotoxin Risk Managment. In this series of six episodes, Dr. Swamy Haladi, Global Technical Commercial Manager for Selko will touch upon various aspects related to mycotoxin analysis. Watch all videos here