Unlocking potential: Understanding the varieties and effects of (yeast) beta-glucans and MOS in animal nutrition

A simple Google search on “beta-glucan products animal nutrition” brings up over two million results in less than a second. But are all beta-glucans the same? And how does the production process determine the product's mode of action? This article will tell you everything you need to know.

Variations in the structure of beta-glucans from cereal, fungi and yeast

Beta-glucans are proven to be highly effective components found in the cell walls of algae, bacteria, fungi, cereal and yeast. The structure of a beta-glucan depends on its source, and, in turn, the beta-glucan’s effect depends on its molecular structure. All beta-glucans comprise a string of multiple linked glucans; the way that the hydroxy group is positioned in the molecule makes it either an alpha (α)-glucan or a beta (ß)-glucan. The way that the different beta-glucans are linked defines the final molecular structure. Bacterial, algae and cereal beta-glucans have a two-dimensional (2D) structure, while fungal and yeast beta-glucans have a three-dimensional (3D) structure.

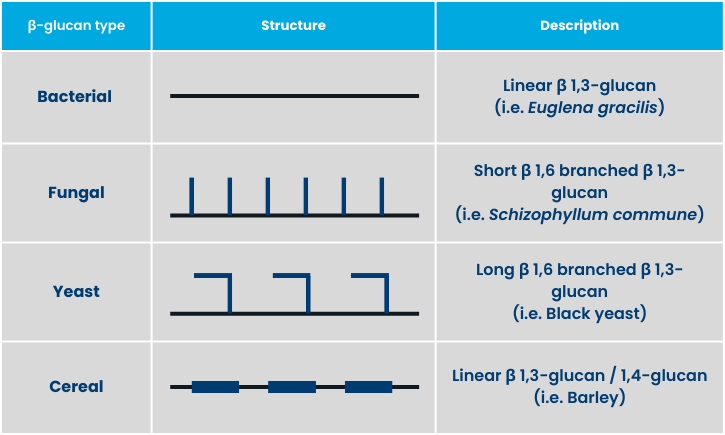

The picture below show the basal molecular structure of bacterial/algae, cereal, fungal and yeast beta-glucans. Beta-glucans can branch in three ways: (1) 1,3 branching, (2) 1,3/1,4 branching and (3) 1,3/1,6 branching. The 1,6 branching changes the molecule’s structure from 2D to a 3D. The source of the beta-glucan defines the length of the molecule attached to the 1,6 branching. Fungi beta-glucans are short-branched, 1,3/1,6 beta-glucans, while yeast cell walls have long-branched, 1,3/1,6 beta-glucans. This is schematically explained in figure below.

Source: Seo et al, 2019

Variations in the structures of beta-glucans

How different beta-glucans activate immune cells, such as macrophages

The first line of immune cells is part of an organism’s innate (non-specific) immune system. These immune cells have many different types of receptors on the surface of the cell walls, that allow them to connect with very specific components. Beta-glucans specifically connect with the dectin-1 receptor. Their efficacy depends on the beta-glucans’ molecular structure. Dectin-1 receptors are present on macrophages and a couple of other immune cells. Since beta-glucans seem to be most effective in macrophage activation, they will be our focus in this article.

Bacterial/Algae (1,3) beta-glucans can signal an immune cell to start excreting inflammatory mediators that stimulate other immune cells to spring into action, but don’t activate the immune cells to act themselves. For example, they can cause a macrophage to start phagocytosis.

Fungal (short 1,3/1,6) beta-glucans can direct immune cells to act against fungal infections through, for example, phagocytosis, but they don’t make a significant contribution to signalling other cells.

Yeast (long 1,3/1,6) beta-glucans have the widest range of action. They can both fully activate immune cells to take action themselves and also make them secrete signals to other immune cells to move into action.

The ability of an innate immune system to rapidly recognise and react to invasive pathogens is crucial for infection control – and the most significant and complete impact comes from long beta-1,3/1,6-glucans.

Yeast beta-glucans

Refining the Google search mentioned earlier to: “yeast beta-glucan products animal nutrition” provides 500,000 results – a bit fewer, but still a huge number. Again, the production process determines a yeast beta-glucan product’s efficacy.

The yeast cell wall: understanding MOS, beta-glucans and chitins

You have learned that yeast beta-glucans are the most effective immune stimulators because of their structure. Now we'll dive into the different types of yeast cell wall products on the market.

But first let’s investigate a yeast cell itself. The cell consists of liquids (cell extract) surrounded by the cell wall, which contains all of the cell's organelles and enzymes. A range of methods and combinations can be used to separate the cell wall from the extract in order to produce the beta-glucan product. These include:

- Autolysis: Activating the intracellular enzymes to solubilise the cell components

- Hydrolysis: Adding enzymes to solubilise the cell components

- Centrifuging: After the cell wall has been broken, using centrifuging to separate the extract from the cell walls.

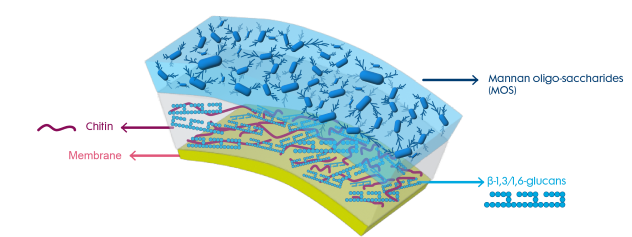

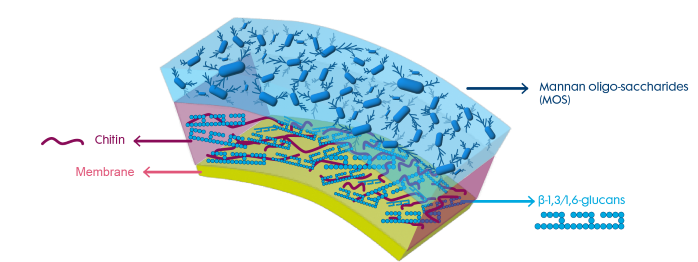

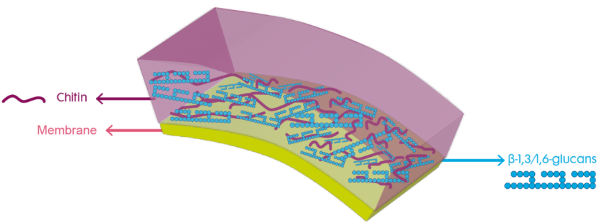

The yeast cell wall exists of a layer of mannan oligosaccharides (MOS), followed by a layer that contains the beta-glucans and some chitin, followed by a membrane that separates the cell extract from the wall.

Chitins are the building materials that give strength to cell walls. Chitins induce an immune response themselves, but given their low presence (<10%) in cell walls, this response is not considered to be significant compared to the impact made by beta-glucans.

The MOS layer is a thick, insoluble and undigestible layer covering the beta-glucans and chitin. Without any further treatment, the beta-glucans will remain covered and will only be able to interact with macrophages at the places where the yeast cell wall breaks open. This provides a small surface area, which significantly limits the interaction between beta-glucans and the immune cells of the animal.

Products in which the MOS layer remains untreated are usually marked as MOS products, as the effect of the beta-glucans is limited by the MOS covering. MOS itself has beneficial effects for the host, which we will discuss later in this article.

As mentioned before, certain treatments can be added to the production process to remove (part of) the MOS layer and increase the surface area of the layer containing the beta-glucans. We call the resulting products “exposed beta-glucan products.” There are two options for exposing the beta-glucans:

- Using chemicals to remove a large portion of the MOS layer

- Using natural enzymes to create holes in the MOS layer

Chemically treated products usually end up with a beta-glucan percentage of 60-85%. The percentage of beta-glucan concentration is largely increased by removing the MOS layer from the product.

Fibosel® is the only product on the market that is treated with natural enzymes. Enzymes remove the MOS layer less aggressively than chemicals, resulting in a beta-glucan content of at least 30%.

Yeast cell walls: understanding the diverse modes of action of MOS and beta-glucans

The immune system is very complex. There are two different types of immune activation in which yeast cell walls interact: (1) pathogen-associated molecular patterns (PAMP) and (2) damage-associated molecular patterns (DAMP).

Beta-glucans trigger PAMP responses; because the body treats the beta-glucans like a pathogen, they migrate them into the Peyer’s patches, where many immune cells are present. This results in an infection-like immune response behind the epithelial cell layer in the intestines. MOS triggers a DAMP response, leading to mucosal regeneration in the mucus layer of the intestines, which covers the epithelial cell layer. There are far fewer immune cells present in this mucus layer, so it doesn’t result in the same immune boost as beta-glucans. To summarise, MOS may prevent pathogens from getting to and through the intestinal barrier, while beta-glucans prepare the immune system for any pathogen invasion that might appear in the future.

The immune stimulation efficacy of a beta-glucan product depends on how well the beta-glucans can connect with macrophages. This depends on two measures: surface area and intact beta-glucan molecular structure. Great surface area with few high quality/intact beta-glucan molecules can lead to a much lower immune response than high quality/intact beta-glucans with a much lower surface area.

Immune cells have many different receptors that connect to different substances, such as pathogens. They are like locks that only connect with a specific key – and these keys are present on all different types of substances. As mentioned, beta-glucans connect to the dectin-1 receptors on macrophages. The more aggressive the treatment to expose the beta-glucans, the greater the risk of damaging these keys, which might result in a lower efficacy when products are compared against each other.

How to recognise an MOS and an exposed beta-glucan product

The are only a very limited number of exposed beta-glucan products available for animal nutrition, due to the complex and expensive treatment that must be added to the production process. A product's technical documents generally include information on the source and type of beta-glucan product it is.

The in feed dosing for exposed beta-glucans for livestock is much lower than for MOS products, since immune fatigue can set in when the immune system is exposed to too many beta-glucans for too long. Dosages in aquatic species are higher, since these animals lack a more complex immune system, and so immune fatigue is not an issue.

The following table can be used as a guideline for beta-glucan products originating from yeast:

|

|

Active components |

|

|

Product type: |

MOS (%) |

ß long 1,3/1,6 glucans (%) |

|

MOS |

> 20 |

< 25 |

|

Exposed beta-glucan (enzymatic) |

< 20 |

Min. 30 |

|

Exposed beta-glucan (chemical) |

< 10 |

60 - 85 |

In this article, we dove into the diverse world of beta-glucans, exploring their structural variations across different sources — including algae, bacteria, fungi, cereal and yeast – and how these differences impact their mode of action, particularly in activating immune cells, such as macrophages. We also discussed the importance of production processes in determining the efficacy of yeast-derived beta-glucan products. If you’re interested in an exposed beta-glucan product, Selko offers Fibosel®, a naturally enzymatic exposed beta-glucan product.